Operation process

RKE Intelligent Detection Industry

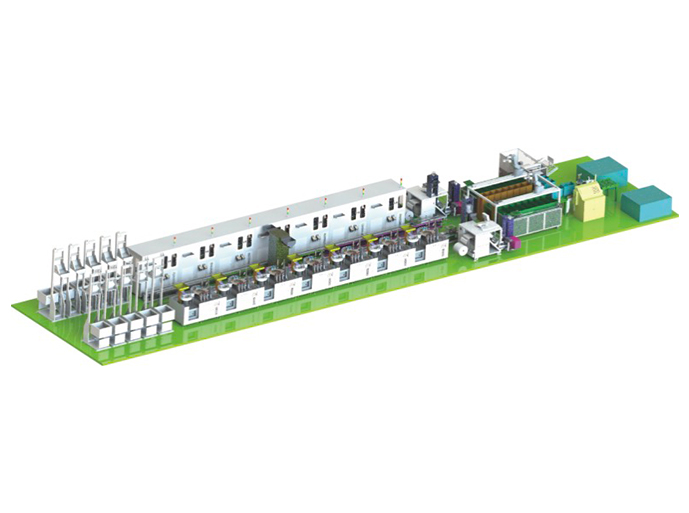

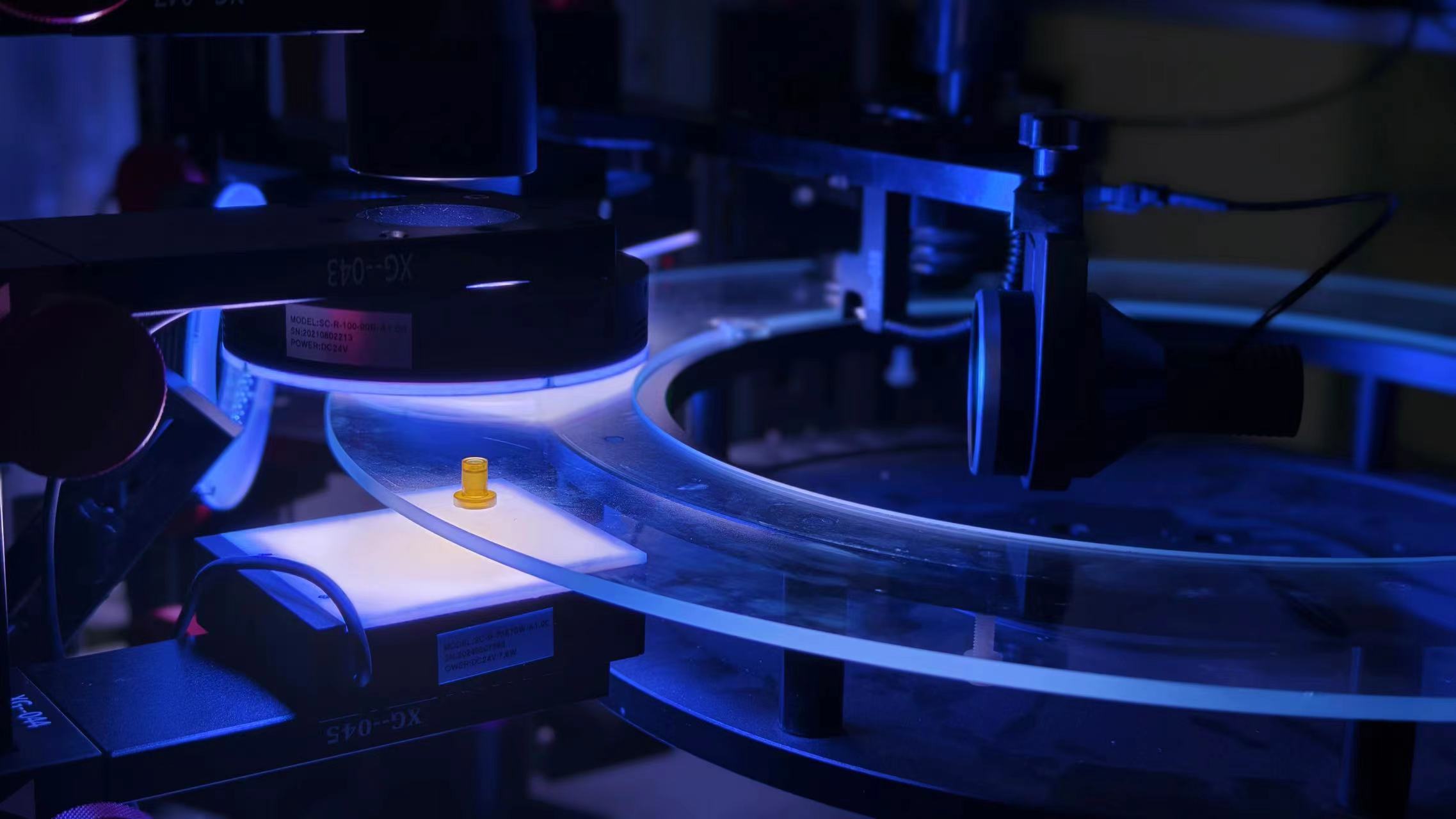

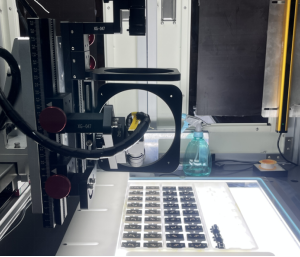

The robotic system is integrated with the production line. The workflow is as follows: a robotic arm picks up items from the conveyor belt and securely handles them using a custom fixture. Positioning and inspection are performed using multi-angle CCD and LED technology. Automated Optical Inspection (AOI) uses machine vision to detect defects, and AI-based classification of anomalies achieves over 99.5% accuracy. Conforming products are then delivered by the robotic arm to a qualified bin or back to the production line. The system features interchangeable fixtures to accommodate different products.

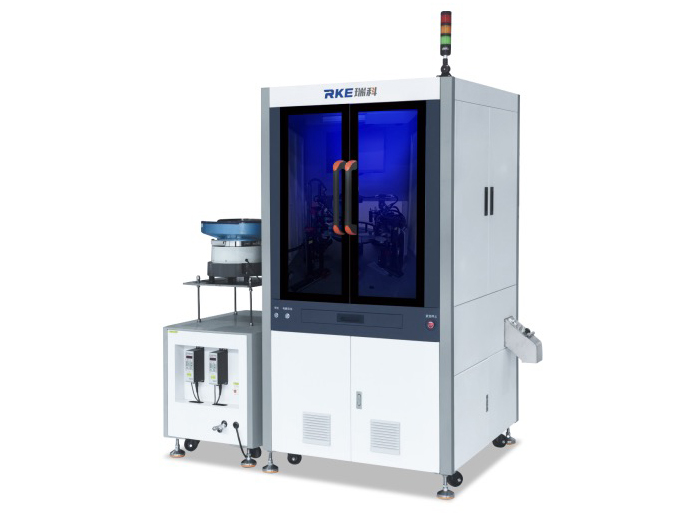

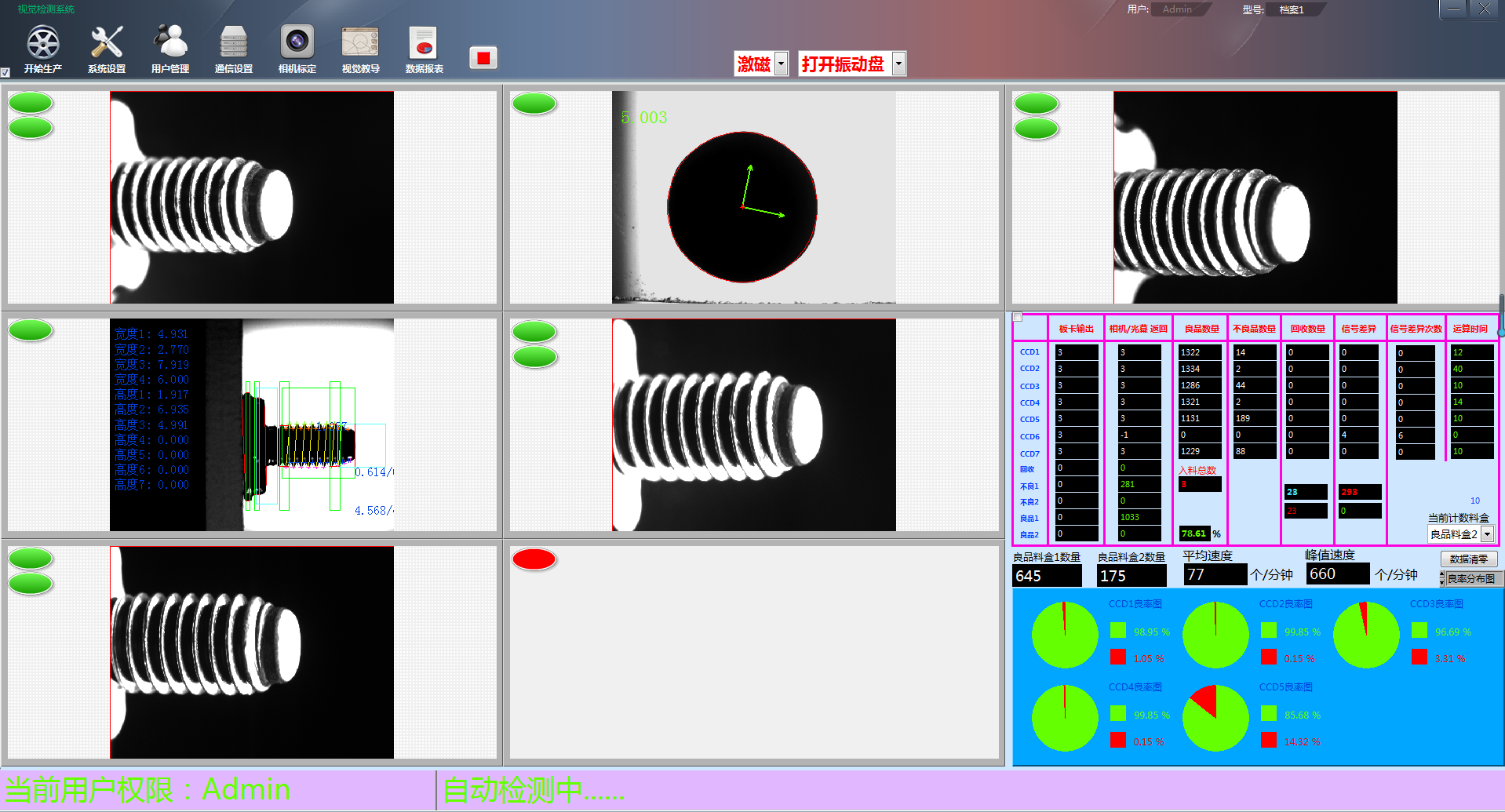

This customized, fully automatic AOI inspection equipment is designed specifically for defect detection of automotive parts. It uses a high-resolution CCD and multi-angle LEDs to capture details, and intelligent algorithms to fully automatically detect, mark, and separate defective products. The software has a user-friendly interface and supports multi-recipe management, parameter adjustment, report export, and rapid detection settings for new parts. It can be customized on demand, ensuring top-level quality control while reducing labor costs and improving production efficiency.

+86 18938290376

rkesales@chinarke.com

about us

Building a world-class visual equipment enterprise

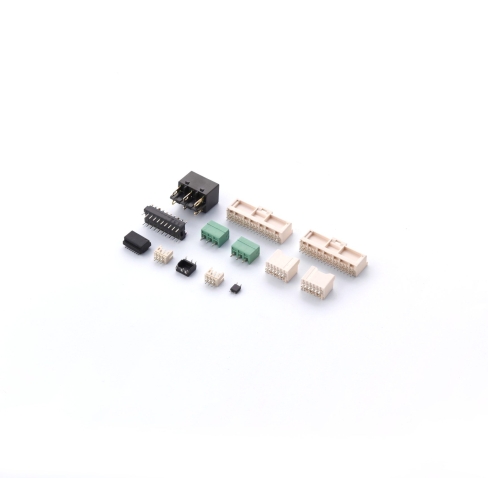

RKE is a leading global supplier of high-quality visual inspection and industrial automation solutions, a leader in industry innovation, and a high-tech enterprise specializing in intelligent equipment such as visual inspection, AI, lasers, CCDs, and industrial robots. The equipment is mainly used in 3C electronics, hardware, fasteners, rubber and plastic, new energy vehicle components, aerospace precision parts, semiconductors, food, medical and other fields.

Our advantage lies in understanding customer needs and industry applications, and actively responding to the constantly changing market. Create greater value for customers with globally leading technology.

Major Equipments

Professional Customized Solutions

RK-1300 Eddy Current Optical Sorting Machine

Designed For The Objects That Can Not Stand Upright, Such As Long Screw, Pulling Caps And Suspensible Piece.

RK-1500 Glass Dial Optical Sorting Machine

RK1550- Automotive Parts Inspection and Testing

RK-1320 Headed Fastener Optical Sorting Machine

With Steel Belt For Suspending The Objects To Be Detected

RK-1920 Stealing Ring Inspection Equipment

Fit For Large o-Ring Products. The First Glass Is Tested For The Front Face With 360 Degree Appearance Of The Inner And Outer Sides, With a Flipping Machanism In The Middle To Turn The Piece Over. The Second Glass Is Tested For The Other Face And 360 Degree Appearance Of The Inner And Outer Sides.

CCD Non-Standard Customization Inspection Machine

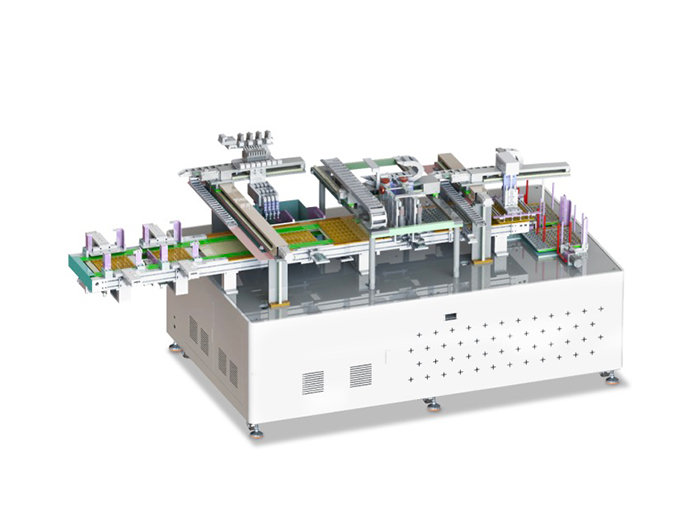

By Using AGV Cars,Coveyor Belts, Modules,Etc., It Is Easy To Achieve Automated Transportation, Positioning, And Handling Of Empty And Full Trays.

Intelligent Unmanned Workshop

Major Equipments

Professional Customized Solutions

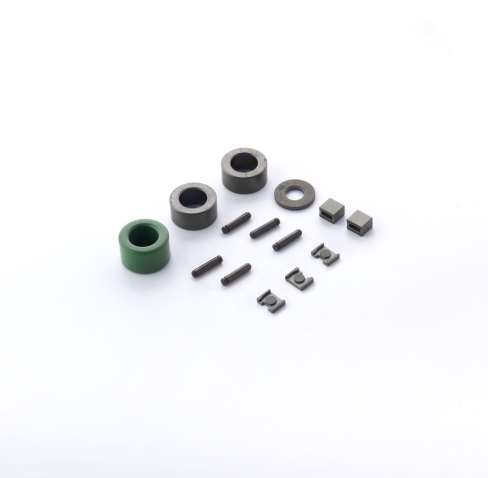

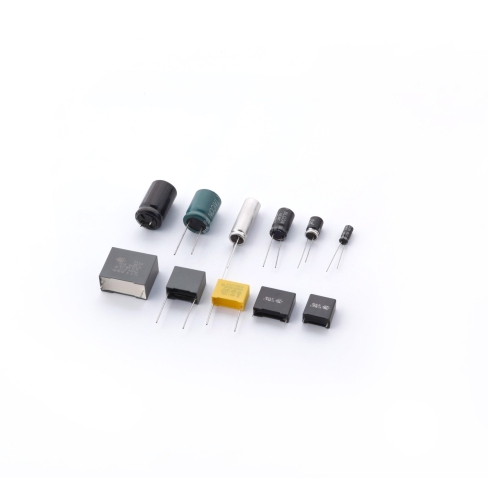

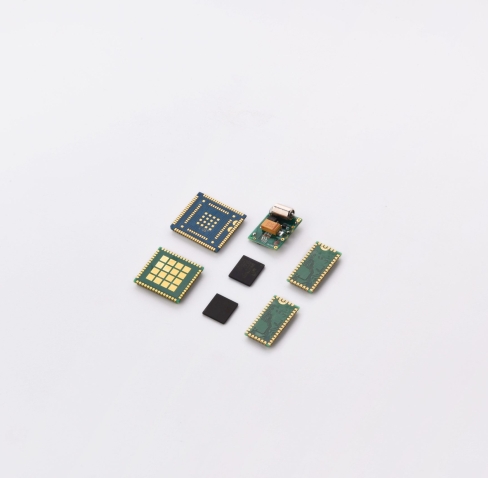

our Application

Application Industry

OUR Solution

Honesty And Pragmatism, Pursuit Of Excellence

The Total Area Of The Company Exceeds 30000 Square Meters

Having Over 150 Intellectual Property Rights

The Company Has Over 300 Employees, Including More Than 120 Engineers

Serving Over 5000 Clients

The Company’s Equipment Has Passed The National “3c” Certification And Iso9001 Quality Management System Certification. From Scheme Design, Contract Signing To Institutional Design, Part Processing, Equipment Debugging,

Our Blog

Latest From Blog

Quality Control Automation via Vision Systems

Precision-driven quality control automation with AI-powered vision systems ensures flawless production. In the fast-paced world of electronics manufacturing, precision and efficiency are non-negotiable. Dongguan RKE

Commerce Bureau Delegation Visits RKE Intelligent

New Year Begins with Inspiring Visit Dongguan RKE Intelligent recently welcomed a delegation led by Yang Rong (Level-4 Researcher of Dongguan Commerce Bureau), Zhao Chaoyang

AOI Company Year End Celebration

As the Year of the Dragon fades and the Year of the Snake begins, we, the RKE AOI Company, gather together to create a brilliant