Machine viison technology significantly enhances industrial automation. It improves production efficiency, product quality, and drives intelligent transformation in manufacturing. Below are the four core functions of machine vision, with specific cases.

Pattern Recognition/Counting Function:

In automotive manufacturing, a machine vision system sorts components based on shape, color, and identifiers. It efficiently directs screws, bearings, and other components to the correct production lines. This system reduces errors and time costs from manual inspection.

Vision Positioning Function:

In electronic device manufacturing, computer vision and robotic arms enable precise positioning. The robot captures component images and calculates coordinates. Visual localization algorithms guide the robotic arm for accurate assembly. This enhances precision and automates the assembly process.

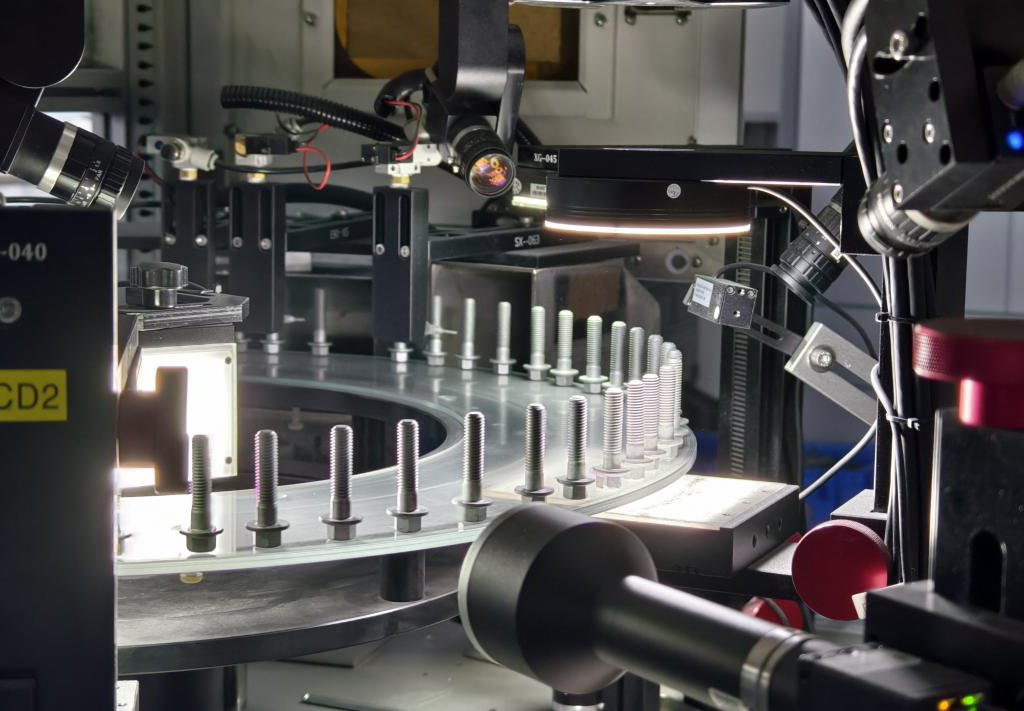

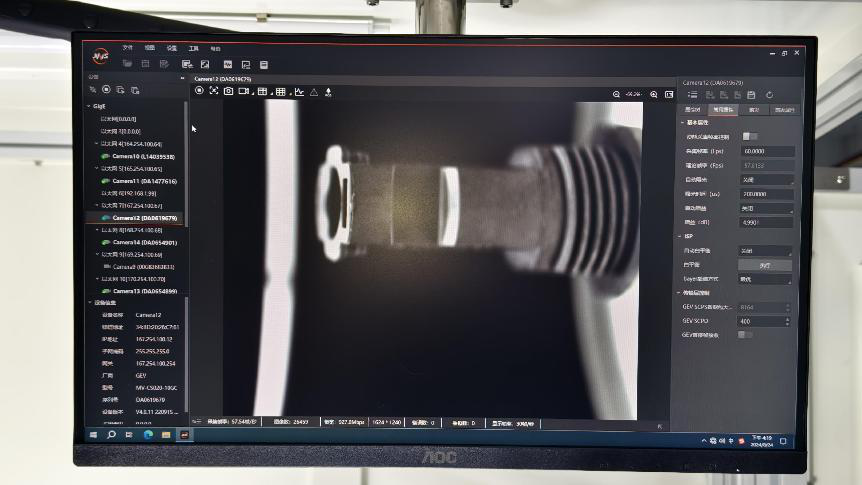

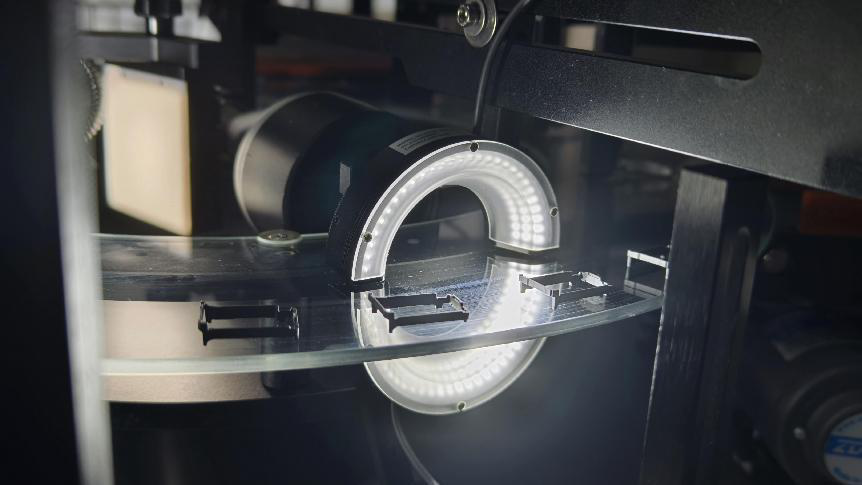

Dimensional Measurement Function:

In the automotive manufacturing process, machine vision technology captures images of fasteners (such as bolts, nuts, etc.) and uses dimensional measurement functions to accurately convert pixel information into actual dimensional data. It can measure key dimensions, such as fastener diameter, length, and thread spacing, and also assess the shape and surface quality of the fasteners. This feature significantly enhances measurement accuracy and efficiency.

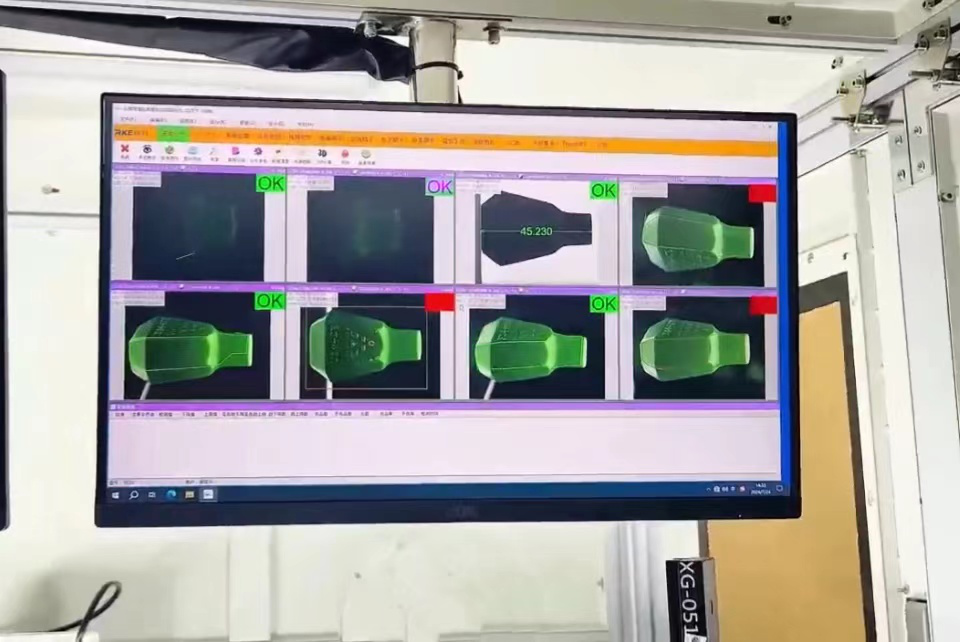

Appearance Inspection Function:

Bottle Appearance Defect Detection System:

In the production of bottles, appearance defects are a key factor affecting product quality. Machine vision technology captures images of various positions on the bottles and automatically identifies and marks defects such as cracks, bubbles, and scratches through visual inspection. This system not only improves the accuracy and efficiency of defect detection but also reduces the subjectivity and missed detection rate associated with manual inspection, ensuring consistent quality when the bottles leave the factory.

From a technical perspective, the complexity of identification, localization, measurement, and detection is steadily increasing. Therefore, to address most of the challenges in visual inspection projects, it is essential to consider all four aspects comprehensively and optimize or adjust them based on specific needs.