- Machine Vision Inspection System

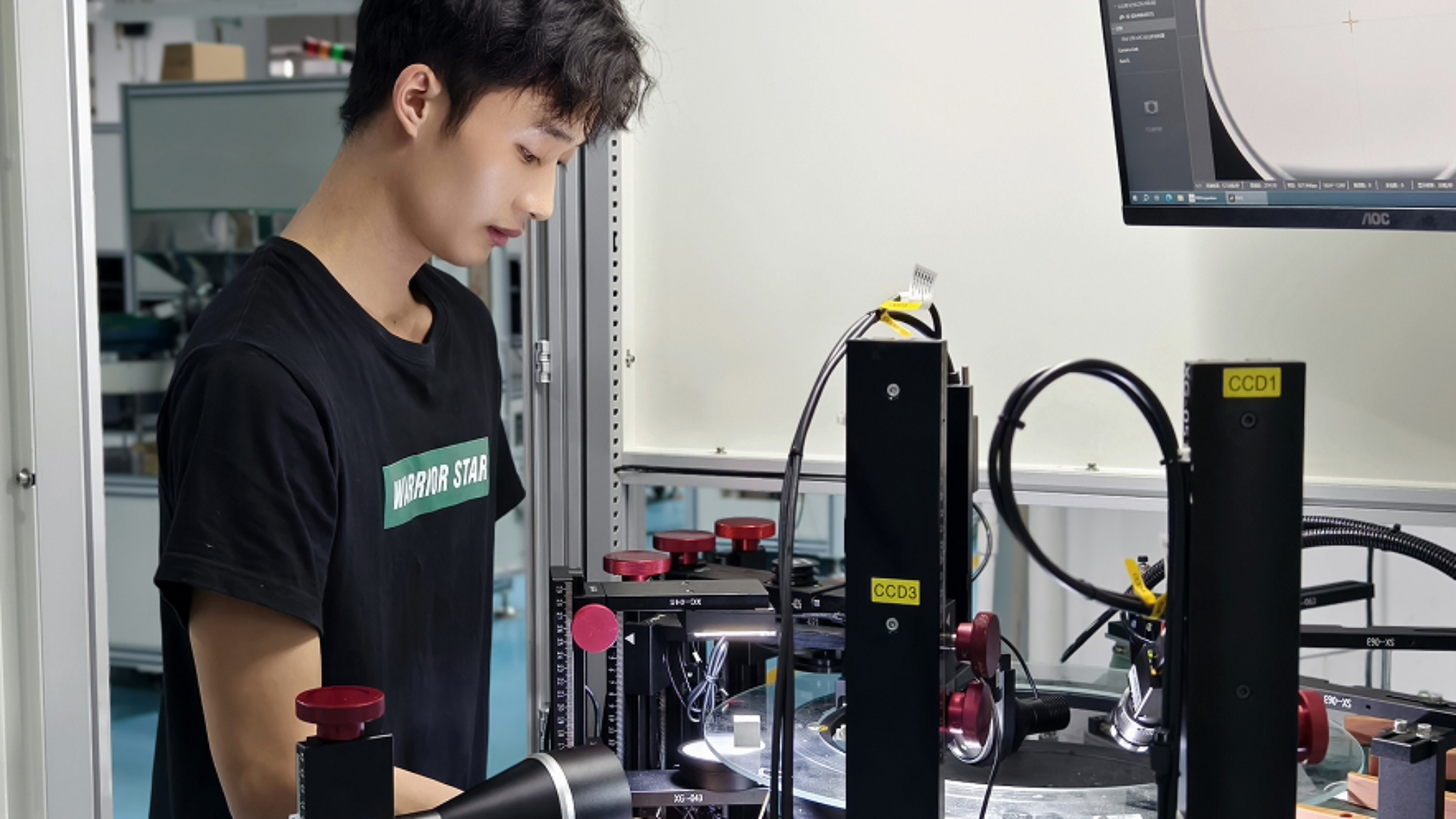

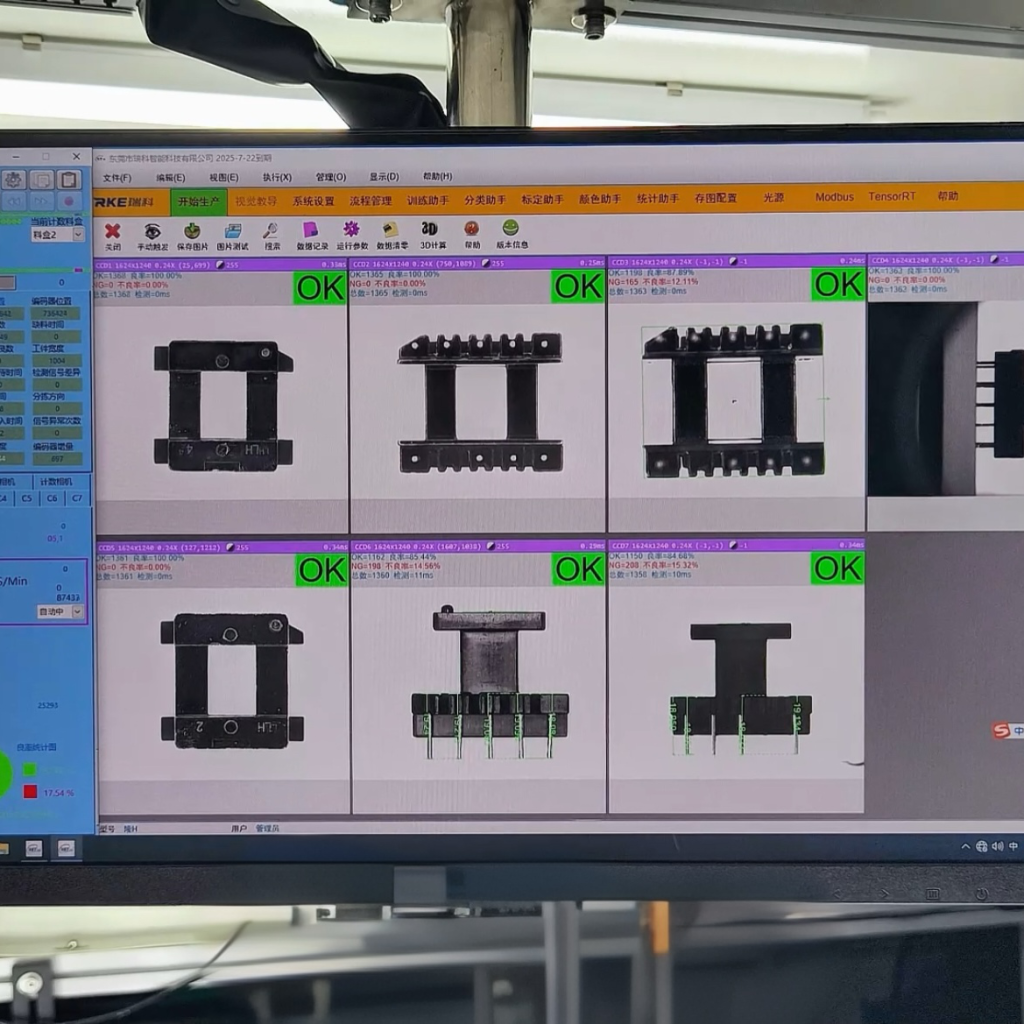

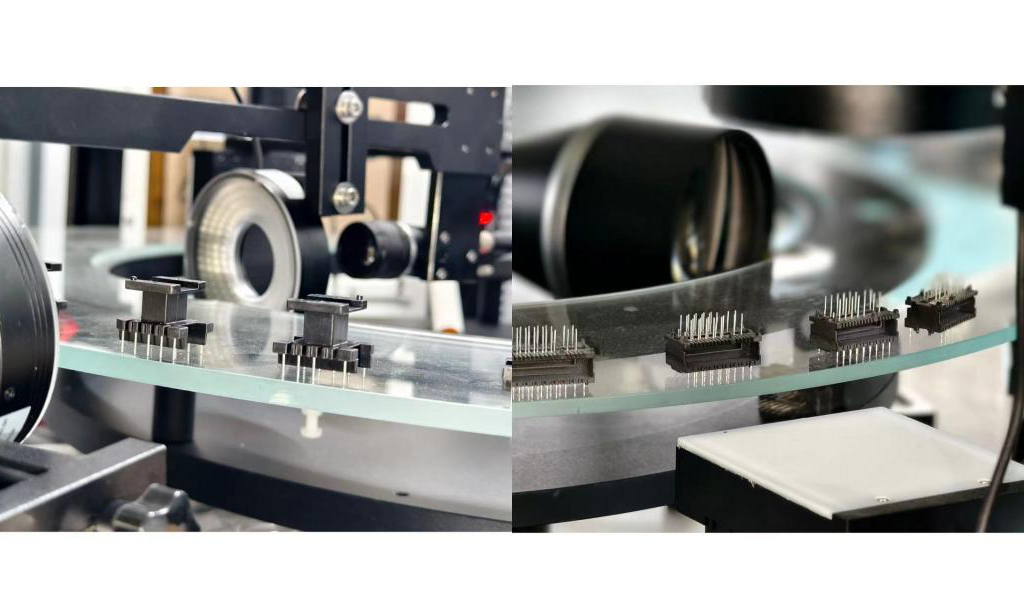

Machine vision inspection software powers this system. The machine uses seven high-precision industrial cameras to capture image data from all angles. Advanced image processing algorithms detect surface defects like missing pins, crooked pins, and damaged edges. The system ensures efficient detection, high accuracy, and strict quality control in manufacturing.

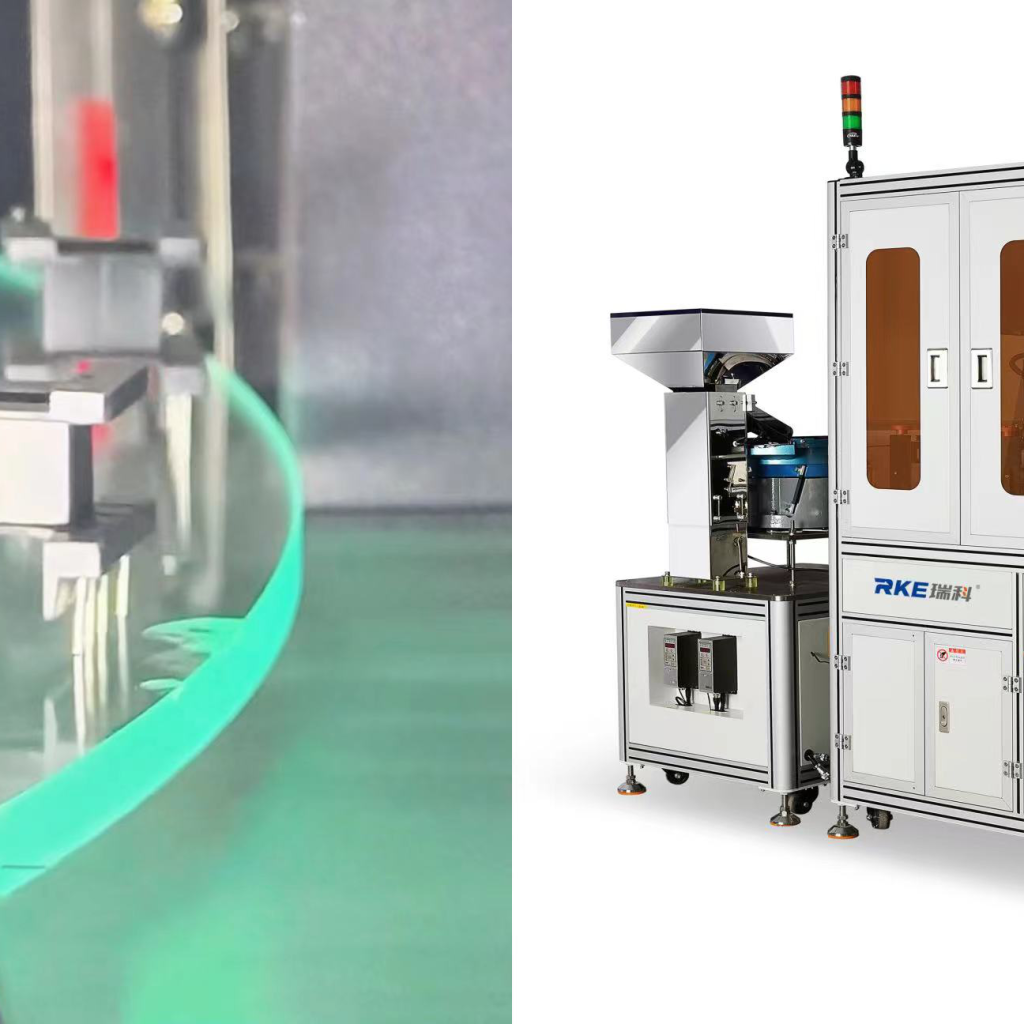

2.Automatic packaging system

The automatic packaging machine integrates with the vision inspection system, ensuring a seamless transition from inspection to packaging. It autonomously counts, labels, and packages connectors based on preset programs. The system ensures high efficiency and accuracy, boosting automation and reducing labor costs.

3.Customized customer service

Customers can flexibly set testing items and standards based on the characteristics of their products and production needs. RKE will provide tailored solutions to meet customer requirements, ensuring that the machine is delivered in the shortest possible time. This customized service model not only enhances the adaptability of the equipment but also reduces customer waiting time.

4.Machine advantages and application prospects

The figure below shows a vision inspection machine designed for detecting connectors. It offers high efficiency, accuracy, and automation. As electronic products evolve and markets expand, vision inspection applications in manufacturing will grow. This will enhance quality control and elevate the electronic manufacturing industry.

Summary

Machine vision technology is advancing to meet diverse customer needs across industries. It adapts to specialized requirements in electronics, automotive, and manufacturing sectors. These systems can detect various defects and dimensions in complex components, enhancing product quality. Machine vision integrates AI and deep learning to improve speed and accuracy. It supports higher automation, boosting production rates while reducing costs. Customizable features allow tailored solutions for different production lines. As these systems evolve, they drive operational efficiency and reduce waste. Companies offering flexible vision solutions will gain a competitive edge in the global market.