In industrial production, precision in defect detection is fundamental, but speed becomes key once precision is achieved. Engineers widely agree that increasing detection speed while maintaining precision is essential for improving production efficiency. In the AOI inspection machine is especially important. Boosting inspection speed without compromising accuracy significantly improves overall throughput. Maintaining this balance in vision systems for manufacturing increases productivity and cost-efficiency.

Speed requirements drive profit growth, especially on 3C electronic product lines like capacitors and resistors. These lines require a speed of 10mm per second. Detection efficiency impacts the production line’s capacity and company profits. Engineers say doubling defect detection speed boosts profits by 25%.

Improving speed is not easy due to algorithm and hardware limitations. Factories must balance three core elements:

- Low cost and high precision: Low-configured graphics cards reduce costs but slow detection, affecting production efficiency.

- Fast cycle time and low cost: Compressing image size lowers costs and improves speed but reduces precision and increases the miss rate.

- Fast cycle time, high precision, and high cost: High-configured graphics cards and cameras increase speed but raise hardware costs, affecting ROI.

Technological integration and innovation

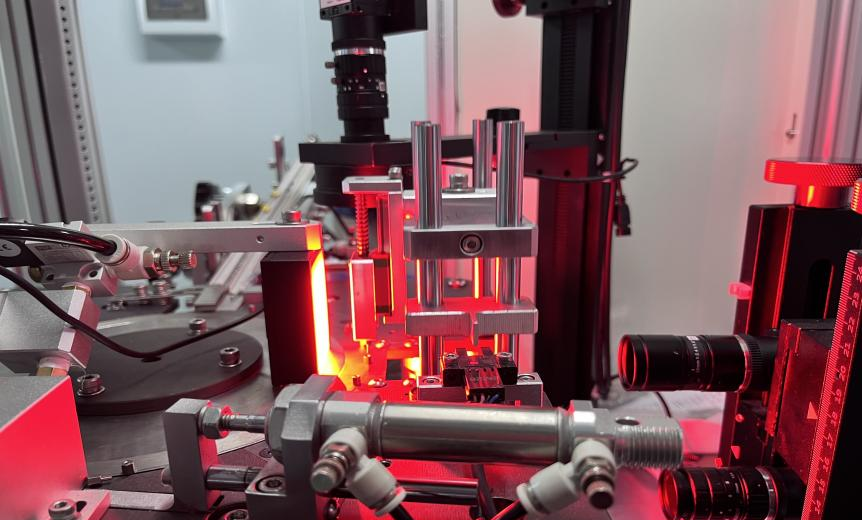

To address these challenges, machine vision, automation, and deep learning must be combined. Machine vision captures fine defects accurately. Automation enables fully automated inspection. Deep learning enhances detection accuracy and efficiency through model development. Integrating these technologies ensures real-time performance for high-speed production.

Different production lines and product features require unique inspection systems. Customized inspection systems are essential to meet specific speed, width, and product requirements. Tailored solutions ensure the best detection results.

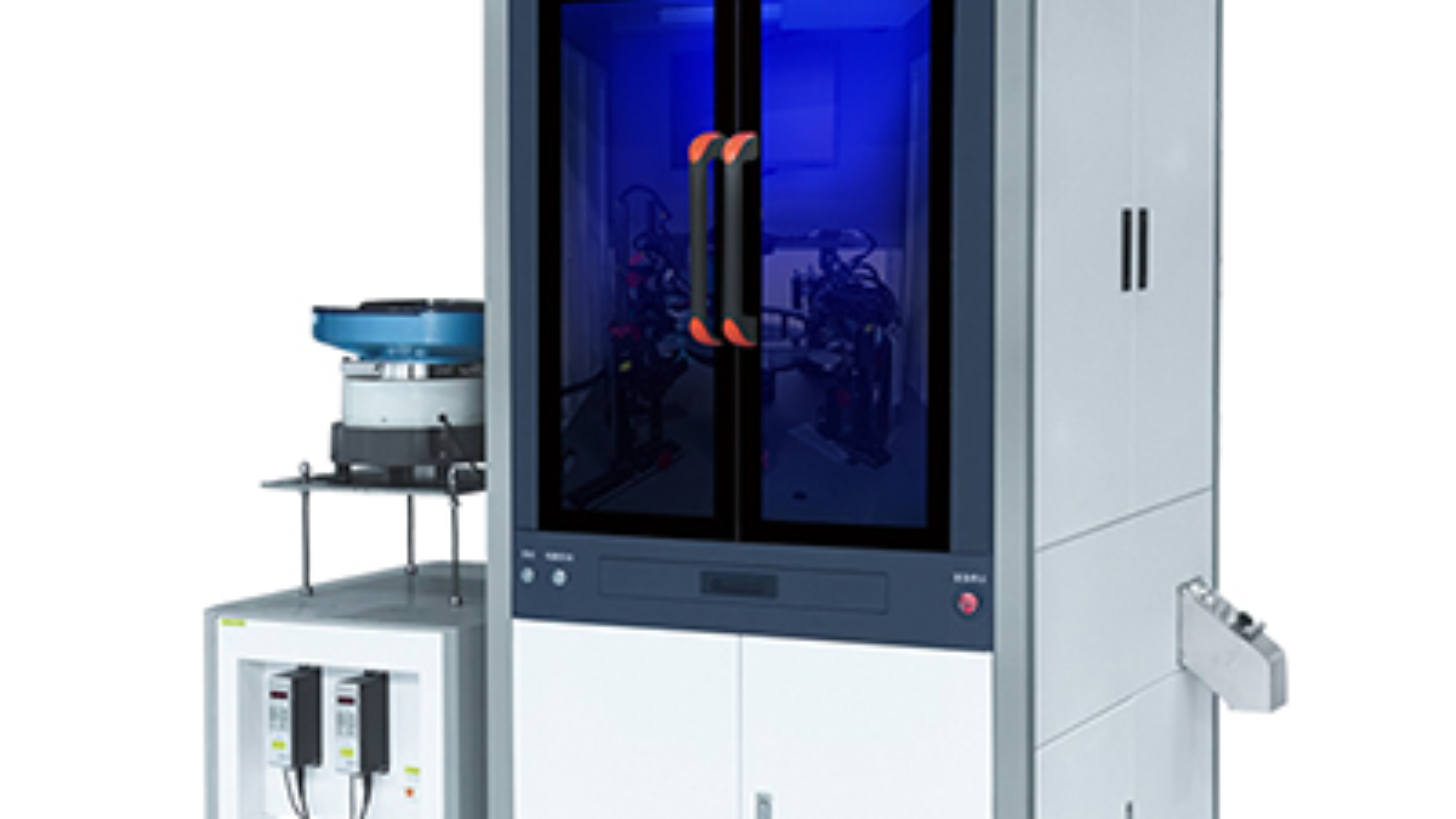

The AOI inspection machine launched by 瑞科 (RKE) is designed based on these needs. It processes a large volume of inspection tasks in a short time while maintaining high precision, with a detection speed of up to 1100 pcs/min, meeting the demands of mass production. This AOI inspection machine integrates multiple advanced technologies and offers customized solutions, aiming to provide users with the perfect solution that meets the needs for fast cycle times, high precision, and low costs.