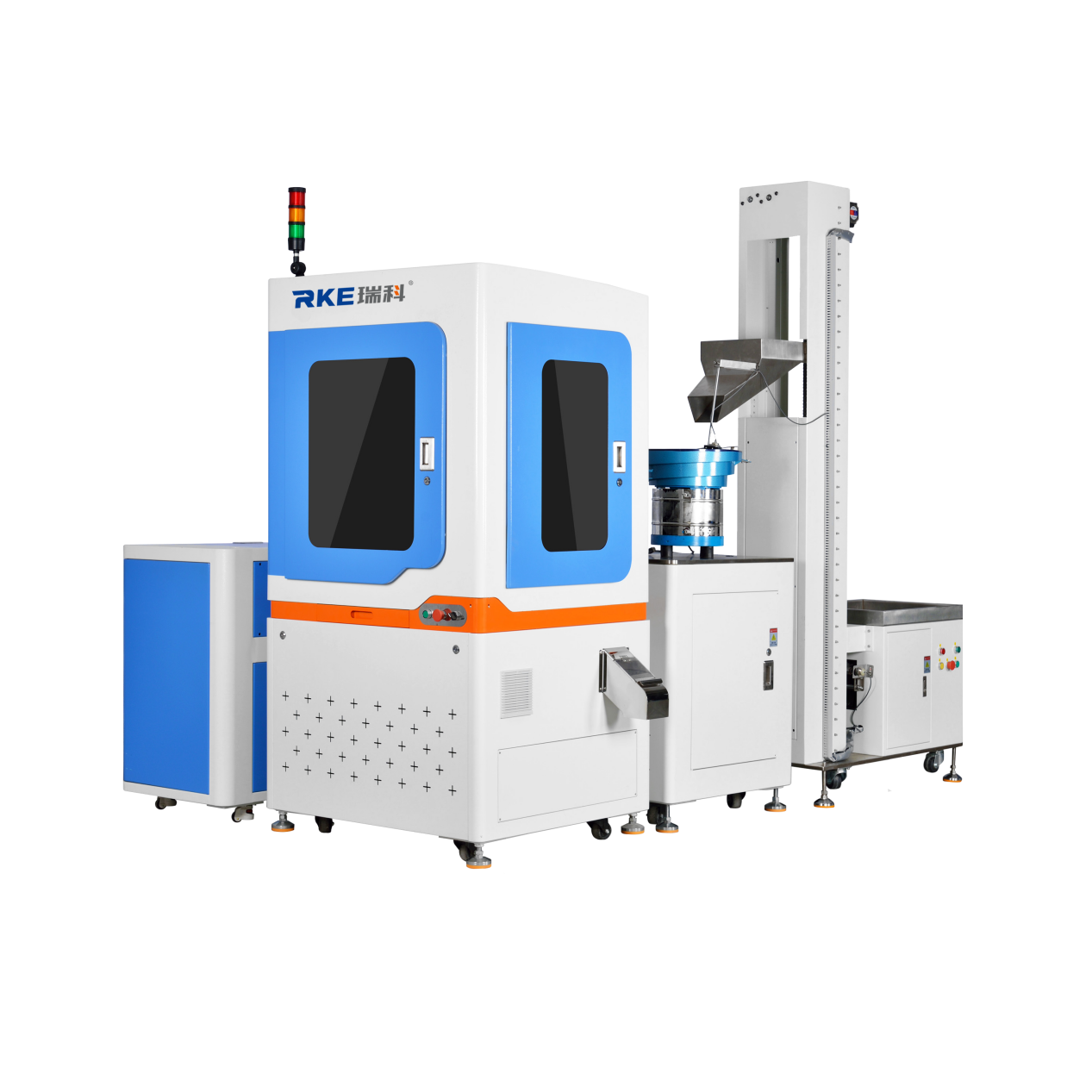

PRODUCT DETAILS

This cutting-edge visual inspection system leverages AI deep learning algorithms and 15-color industrial cameras to deliver ultra-precise defect detection across 15 product surfaces. Designed for flexibility, it detects a wide range of flaws—including pressure injuries, pits, material variations, and color discrepancies—while integrating conveyor belt unloading and rotating feed box collection for seamless production workflows.

Key Features

Advanced AI Deep Learning Technology

- 15-Color Cameras: Captures high-resolution images to identify subtle defects like color gradients, surface textures, and material mismatches that are invisible to traditional monochrome systems.

- AI Deep Learning: Trains on custom datasets to distinguish between genuine defects and acceptable process variations, reducing false positives by 30% up to 90%.

Comprehensive Surface Testing

- Inspects 15 predefined surfaces per product for pressures, pits, scratches, and dimensional deviations with **±0.01 mm accuracy**.

- Supports multi-material analysis (e.g., plastics, metals, composites) to ensure compliance with industry standards.

Efficient Workflow Integration

- Conveyor Belt Unloading: Automates product transfer post-inspection.

- Rotating Feed Box: Ensures consistent orientation and feeding of components during testing.

- Achieves 200 parts per minute while maintaining precision for high-volume production lines.

Technical Specifications

| Parameter | Specification |

|---|---|

| **Length (mm)** | 1–20 |

| **Accuracy (mm)** | ±0.01 |

| Speed (pcs/min) | 100–300 |

| **Pressure (kg/cm²)** | 7 |

| **Voltage (V)** | 220 |

| **Power (W)** | 2000 |

| **Net Weight (kg)** | 650 |

| **Dimensions (LWH)** | 1600×1100×1800mm |

| Cameras | 15 Industrial Cameras |

RELATED PRODUCT

Contact

HOW TO CONNECT