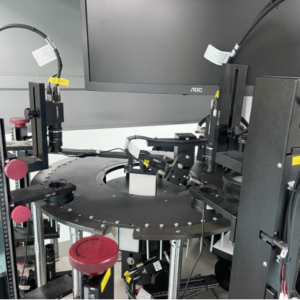

The automated optical inspection machine for automotive parts

- Types:

Glass plate optical sorting machine

- Suited for:

Auto nuts, auto screws, tire valves, oil seals and other auto parts

- Inspection Accuracy:

±0.01mm

PRODUCT DETAILS

The vision inspection machine ensures stable, reliable performance without stoppages. Unlike vibration-based systems, it operates smoothly, making it ideal for delicate components that require gentle handling. The automated optical inspection machine quickly inspects items while maintaining high accuracy, enabling real-time detection of defects at fast production speeds.

This machine excels at inspecting screws and fasteners, providing a 360-degree view from all angles. It can detect a variety of defects, such as thread damage, burrs, head cracks, and verticality issues, all with impressive precision. The system rotates each screw on the index plate to thoroughly examine every aspect of its geometry and surface quality, ensuring no defect goes unnoticed.

The automated optical inspection machine features a customizable steel rotary index plate that accommodates different diameters of workpieces. This flexibility allows it to handle a wide range of screws and fasteners, from small to large components, meeting diverse production requirements.

Combining speed, accuracy, and vibration-free operation, the vision inspection machine is the ideal solution for high-volume manufacturing environments that demand consistent, top-quality inspection.

| Inspecting products | Technology parameters | Features |

|

Customized service can be provided according to the detect demand. |

|

RELATED PRODUCT

Contact

HOW TO CONNECT