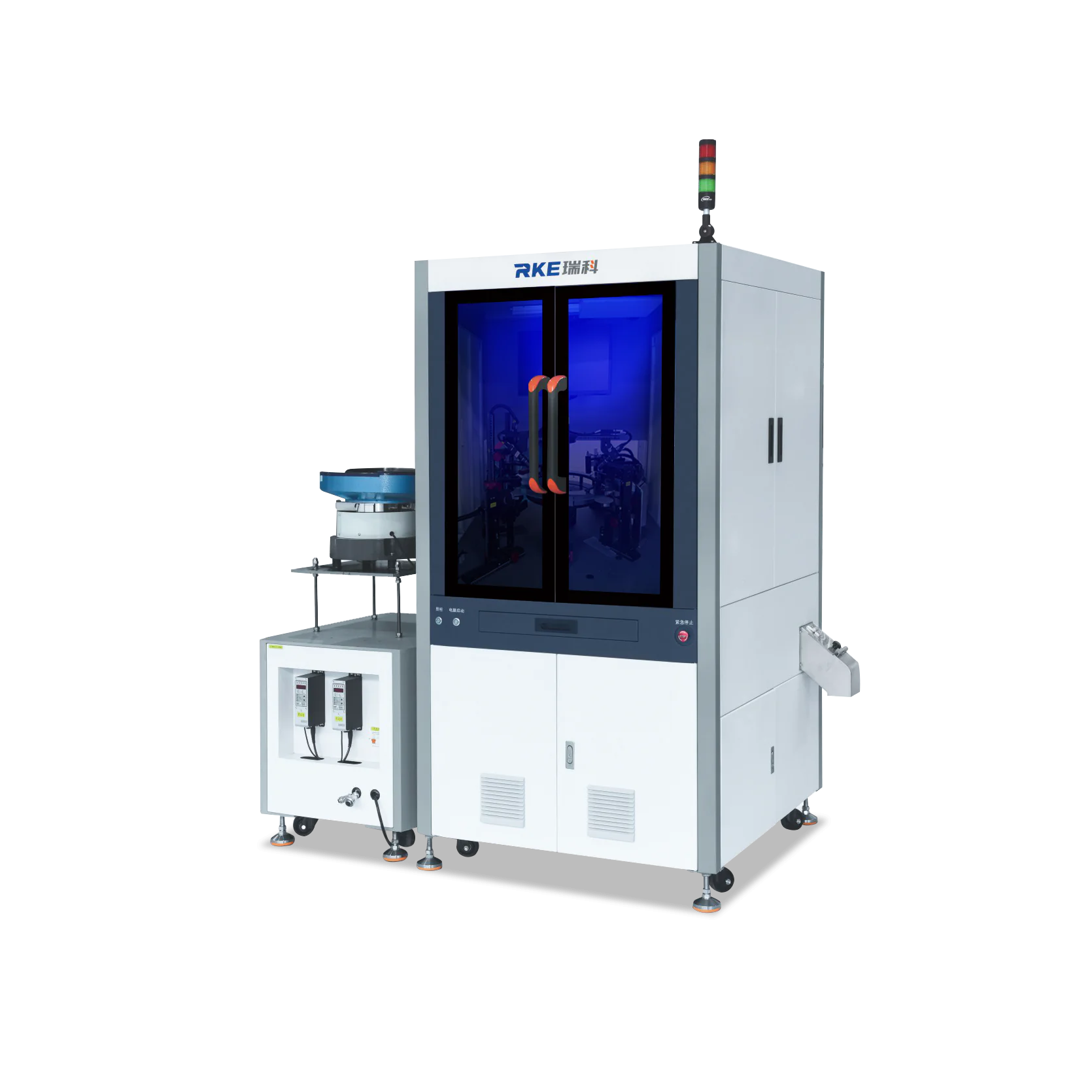

Automatic screw machine for precise inspection

- Types:

Glass plate optical sorting machine

- Suited for:

Screws, micro screws, plastic and rubber parts, electronic component and small parts

- Inspection Accuracy:

±0.01mm

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

PRODUCT DETAILS

Automatic screw machine for precise size and appearance inspection

The glass plate inspection machine is specifically designed for objects that can be steadily placed on the inspection plate, leveraging high transparency glass for clear and accurate detection. This machine is engineered to handle a wide range of products, including fasteners, mobile phone parts, plastic products, electronic components, and special-shaped hardware. Its versatility makes it a valuable tool in various industries, ensuring high-quality output.

Integration with Automatic Screw Machine

The device can be seamlessly integrated with an automatic screw machine, enhancing its functionality for screw inspection and sorting. By incorporating features like laser marking, automatic counting, packaging, and feeding, the machine streamlines production processes. This integration allows for efficient and precise handling of screws, ensuring they meet stringent quality standards before being used in final products.

Efficient and User-Friendly Design

The glass plate inspection device is designed with user convenience in mind. It allows for quick replacement of parts and easy operation, minimizing downtime and maximizing productivity. The machine’s ability to adapt to different inspection requirements makes it a flexible solution for diverse manufacturing needs.

Versatile Applications Across Industries

This device is not limited to a single industry; it can be used in automotive, electronics, aerospace, and consumer goods manufacturing. Its wide detection range ensures that it can handle various components, from small fasteners to complex-shaped hardware. The integration of advanced features like laser marking and automatic counting further enhances its utility in modern production environments.

By combining precision, versatility, and efficiency, the glass plate inspection device is an essential tool for maintaining high-quality standards in manufacturing. Its ability to work alongside an automatic screw machine and other production systems makes it a comprehensive solution for modern quality control needs.

| Technology parameters | Features |

Note: Customized service can be provided according to the detect demand. |

|

RELATED PRODUCT

Contact

HOW TO CONNECT