Customized Automated Vision Inspection Equipment

- According to customer needs, one-stop inspection can be customized.

- Using vision positioning for material loading and film application.

- By camera recognition and robot positioning, automatic correction and positioning can be perfectly achieved, and by using servo modules and vision positioning, correction and positioning can be easily achieved.

PRODUCT DETAILS

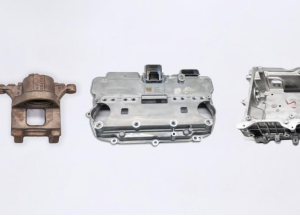

Customized Automated Vision Inspection Equipment deliver tailored solutions for manufacturers requiring flexible, high-precision quality control. These systems integrate vision positioning, robotics, and advanced components to automate material loading, film application, and real-time correction, ensuring accuracy and efficiency.

Core Features & Advantages

One-Stop Customization

- Configured based on client-specific requirements, including product dimensions, material types, and production workflows.

Vision-Guided Automation

- Material Loading & Film Application:

- Cameras and servo modules (e.g., Mitsubishi motors) precisely guide robotic arms for consistent positioning.

- Automatic Correction:

- Real-time camera recognition adjusts robot paths for misaligned parts, reducing downtime by 40% .

- Material Loading & Film Application:

High Stability & Reliable Components

- Built with proven hardware including Keyence/Cognex sensors, SMC pneumatic modules, and Robuster actuators, ensuring long-term durability in harsh environments.

- Compliance with ISO 10360-5 standards for measurement accuracy and IEC 60204-1 safety certifications.

**Why Choose Custom Solutions?**

- Competitive Edge: Unique configurations address niche challenges like asymmetric product designs or multi-material assemblies.

- ROI: Increased yield rates (up to 25%) and reduced labor costs (50% savings per operation) drive profitability.

RELATED PRODUCT

Contact

HOW TO CONNECT