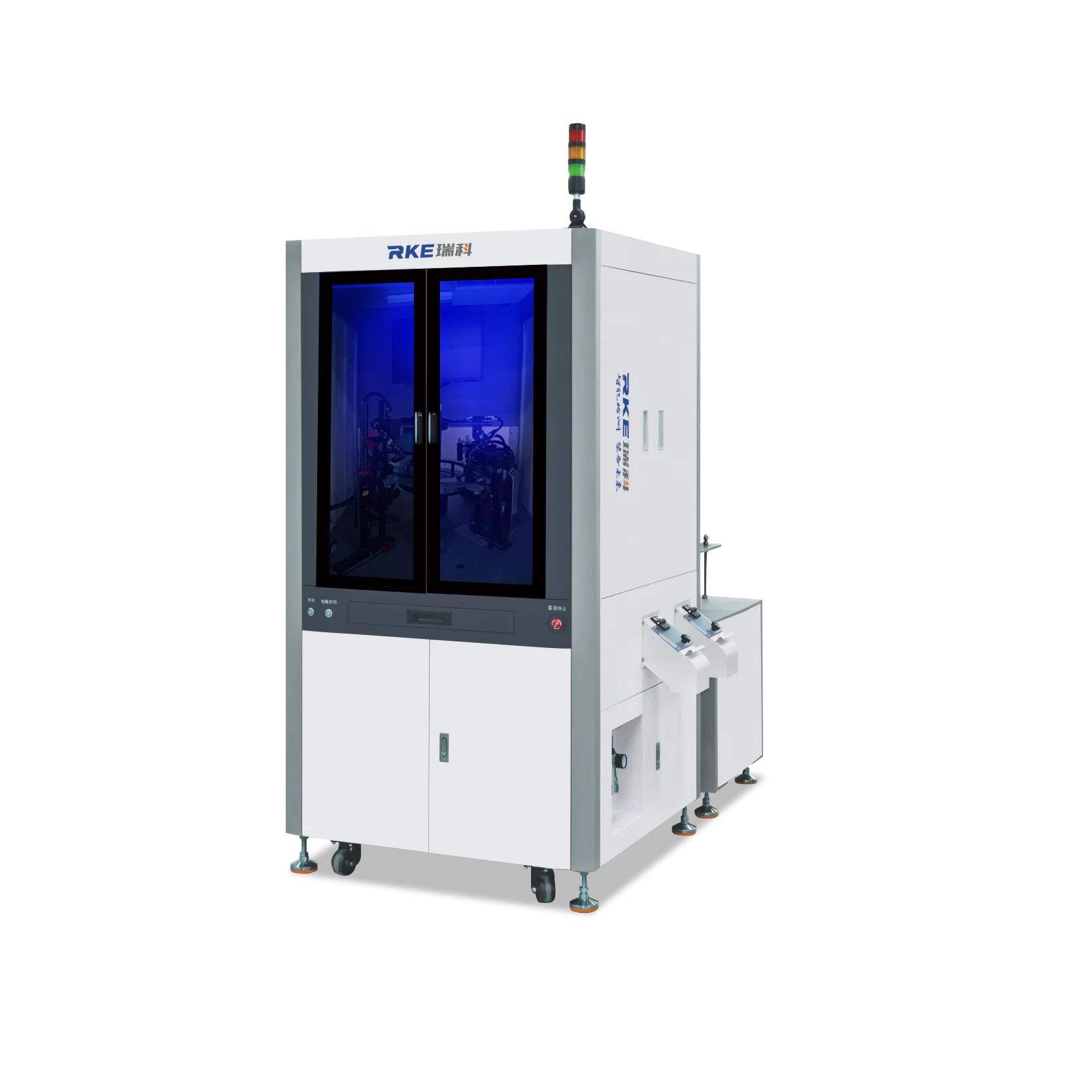

PRODUCT DETAILS

This customizable visual inspection system is specifically designed for new energy components such as battery casings, electrode sheets, and motor parts. It leverages AI-powered visual technology and industrial cameras to detect defects like scratches, dimensional deviations, color inconsistencies, and material flaws with **±0.01 mm accuracy**, ensuring compliance with strict quality standards for clean energy manufacturing.

New Energy Visual Inspection Equipment Key Advantages

Universal Compatibility for New Energy Parts

- Detects a wide range of defects (scratches, notches, burrs, color variations) and verifies critical dimensions (5–40 mm) in components like lithium-ion battery casings or solar panel connectors.

- 6–8 additional cameras provide multi-angle coverage for complex shapes and multi-material parts (metals, plastics, composites).

Flexible Configuration

- Adjusts to project-specific needs: inspection speed (200–1000 pcs/min), pressure tolerance (7 kg/cm²), and dimensional range (5–40 mm).

- Modular design ensures seamless integration with existing production lines.

High-Speed Precision for Clean Energy

- Processes 200–1000 components per minute while maintaining **±0.01 mm accuracy**, crucial for high-volume battery or motor production.

- Early defect detection minimizes waste and boosts efficiency in renewable energy sectors.

Robust Technical Specifications

- Power: 2000W | Voltage: 220V | Weight: 650kg | Dimensions: 1600×1100×1800mm.

- Equipped with industrial cameras for real-time, high-resolution imaging of intricate part details.

RELATED PRODUCT

Contact

HOW TO CONNECT