PRODUCT DETAILS

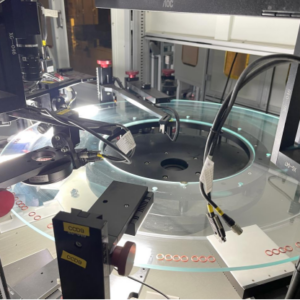

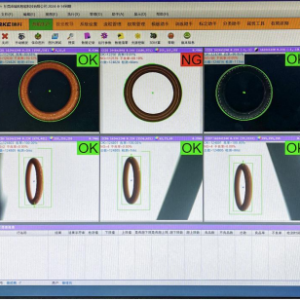

A high-speed automated inspection system designed for O ring components, ensuring 360° dimensional and visual verification of both inner and outer surfaces. The system integrates orientation correction, defect detection, and rejection capabilities to maintain strict quality control in high-volume production lines.

Key Features

Dual-Side Inspection

- First Pass: Inspects front face (inner/outer surfaces) with 360° coverage using an automatic flipping mechanism.

- Second Pass: Inspects the reverse side (inner/outer surfaces) after flipping.

Orientation Validation & Rejection

- Automatically detects and removes parts with incorrect orientation (e.g., flipped sides) to prevent assembly errors.

Modular Camera Configuration

- Supports 10–25 industrial cameras for customized testing requirements (e.g., surface defects, dimensional analysis).

High-Speed Performance

- Operates at 100–300 pieces per minute (pcs/min), suitable for large-scale production demands.

Technical Specifications

| Category | Parameter |

|---|---|

| Product Size | 5–80 mm |

| Detection Accuracy | ±0.01 mm |

| Speed Range | 100–300 pcs/min |

| Environmental | Barometric Pressure: 7 kg/cm² |

| Power | Voltage: 220 V, Power: 3,000 W |

| Cameras | Industrial Cameras (qty: 10–25) |

| Physical Dimensions | 1350 × 1100 × 1800 mm (LWH) |

| Net Weight | 650 kg |

Applications

- Ideal for O ring components, seals, or similar components requiring precision inspection of both sides.

- Ensures consistent orientation and dimensional accuracy in mass-production environments.

Advantages

- Efficiency: Combines rapid throughput with comprehensive 360° inspection capabilities.

- Flexibility: Camera configurations adapt to diverse testing needs (e.g., defect detection, metrology).

- Reliability: High precision (±0.01 mm) guarantees detection of even subtle defects.

RELATED PRODUCT

Contact

HOW TO CONNECT