PRODUCT DETAILS

This electronic component visual inspection equipment uses a high transparent glass platform to stabilize objects during testing, ensuring even subtle defects are detected with exceptional accuracy. While traditionally used for precision electronic components such as resistors, capacitors, and transistors, its adaptability extends to advanced ceramic parts like semiconductor substrates and optoelectronics materials. By leveraging AI-driven visual analysis, the machine achieves real-time defect detection across a wide range of applications.

Detection Scope

- Electronics Testing

The system verifies critical dimensions—including length, height, and diameter—while identifying common defects such as mixing, deformation, burrs, and scratches in components like diodes and transistors. It also checks for printing errors, poor stitching, notches, and black spots, ensuring compliance with tight manufacturing standards.

- Ceramic Component Analysis

For polyhedral ceramic parts such as vacuum ceramics and piezoelectric materials, the machine examines dimensional deviations, surface flaws like chipping edges, and structural integrity. Additionally, it supports advanced material analysis for optoelectronics ceramics and insulator parts used in semiconductor and aerospace industries.

Core Technology

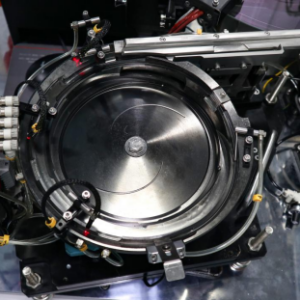

Stable Platform Design

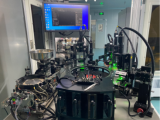

The high-transparency glass platform minimizes movement during inspection, accommodating irregularly shaped objects while maintaining positional accuracy.AI-Powered Visual System

Equipped with up to 8 industrial cameras, this system captures high-resolution images and employs machine learning algorithms to detect defects with **±0.01 mm precision**.Intelligent Analytics

Real-time data processing distinguishes between genuine defects and acceptable variations, significantly reducing false positives through adaptive thresholding techniques.

Key Advantages

- Universal Compatibility

It supports both miniature electronic components (e.g., chip resistors) and large ceramic assemblies (e.g., vacuum tube casings) within a 5–40 mm dimensional range, making it versatile for diverse production needs.

- Efficient & Scalable Operations

Processing 200–1000 parts per minute, the system balances speed with precision, ideal for high-volume manufacturing lines. Its modular design simplifies integration with existing production equipment.

- Robust Industrial Performance

Rated for 220V voltage and 7 kg/cm² pressure tolerance, it operates reliably in industrial environments. The compact footprint (1600×1100×1800mm) and lightweight structure (650 kgs) optimize space utilization.

RELATED PRODUCT

Contact

HOW TO CONNECT