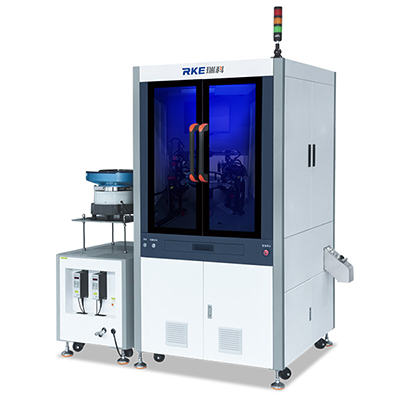

Ceramic Spacer Vision Inspection Machine

Ensure quality. Eliminate defects. Scale production with our vision inspection machine. This ceramic spacer inspection system uses vibration disc feeding and 3 CCD industrial cameras for precise detection. It is equipped with AI-driven visual inspection software to identify dimensional errors, surface scratches, edge chipping, and other appearance defects.

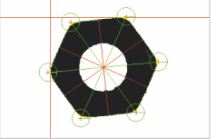

The machine inspects each product for key dimensions such as inner diameter, outer diameter, and height. With a detection speed of 200 pcs/min and an accuracy of ±0.01mm, it ensures that every spacer meets strict drawing requirements. The rotating glass disc allows full 360-degree inspection, catching flaws that manual checks often miss.

Automation and AI integration help manufacturers maintain high throughput without sacrificing quality. Operators can focus on production while the system guarantees zero-defect output. The machine combines speed, precision, and reliability, ensuring consistent product quality and reducing waste. Upgrade your production line with this intelligent solution and protect your brand with every part inspected.

PRODUCT DETAILS

Advanced Ceramic Spacer Vision Inspection Machine for Zero-Defect Production

NO | PARTS | MODEL | QTY | FUNTIONS/NOTES |

1 | Feeding device | For design | 1 | Feeding |

2 |

Solenoid valve

| American MAC- 24VDC | 3 | Blowing( Out-let ) |

3 | Optical | LL-TB02 Japan keyence | 1 | Sensor |

4 | Optical sensor | Japan keyence | 1 | Sensor system |

5 | HD CCD Camera | Basler | 8 | Vision Detect |

6 | Camera | Original Industry camera | 8 | Automatic detect |

7 | LED source | RKE 50*50MM light source | 8 | Lighting |

8 | source control | RKE control | 1 | Control sources |

9 | DD MOTOR | RKE motor | 1 |

For more accuracy |

10 | IO Card | Gugao IO card | 1 | Control system |

11 | outlook | Standard 6063 +Alum | 1 | durable |

12 | Glass Plate | RKE industry glass | 3 | pervious to light , high accuracy |

13 | Feeding trucking | CS-1 for level trucking | 1 | automatic feeding |

14 | optical inspection software | American labview software | 1 |

Newest AI technology |

15 |

Stainless steel vibrating disk |

For design | 1 |

For automatic feeding |

16 | LED | AOC 21 Inch | 1 | Colorful |

17 | Control computer | RKE computer | 1 | CPU 17-3060 Store:DDR4:8G, Disk:240G |

18 | Machinery : | For design | 1 | Rke control |

19 | For electrics | power +control+switch+cable system | 1 |

Safety+ clearly |

20 | Manual | Manual book | 1 | For using |

21 | Tools |

Universal standard hex wrench

| 1 | For testing |

22 | Outlet | OK/NG/Separate | 3 | RKE design |

RELATED PRODUCT

Contact

HOW TO CONNECT