Vision inspection machine for high-speed sorting of fasteners

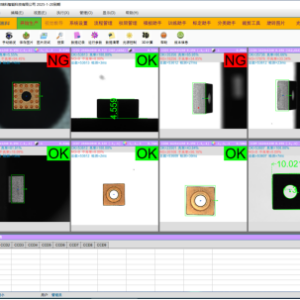

AI-Based Vision inspection Machien For Internal And External Defect Detection

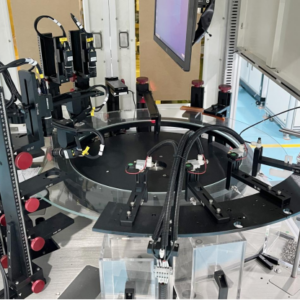

The AI vision inspection machine integrates cutting-edge vision inspection machine technology and a glass dial transmission system, offering advanced automated sorting and inspection solutions. This automatic vision machine is specifically designed for products with high appearance standards, ensuring precise detection and sorting of both internal and external defects through its full 360-degree inspection capability.

The vision inspection device is adaptable to various inspection requirements, providing flexibility to meet specific quality control needs. It can be easily customized and upgraded to accommodate different precision levels, making it suitable for a wide range of industries, including electronics, automotive, and consumer goods.

As an aoi inspection machine, it offers unmatched efficiency in optical sorting and defect detection. Its modular design allows for integration into vision systems for manufacturing, making it ideal for high-speed production environments. This automated optical inspection machine guarantees consistent and reliable results, ensuring top-quality products in every batch.

PRODUCT DETAILS

| Vision inspection machine introduce | Specifications |

|

|

| Features | Vision system principles and mechanisms |

|

|

| FAQs |

|

|

RELATED PRODUCT

Contact

HOW TO CONNECT