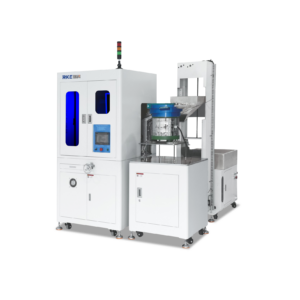

Optical Sorting Machine For Fasterner

Optical inspection machine with Eddy current system for inspecting hardness and separating non-ferrous metal

Functions:

- Material Mix-Up Detection: Identifies if different materials have been mixed together.

- Heat Treatment Detection: Checks for the presence or absence of heat treatment and identifies poor heat treatment.

Suited for:

- Screws, studs, and cylinder-type objects, which may require specific inspection to meet quality standards.

Features:

- The machine can be customized, starting with a standard type or large type base, depending on your production requirements.

- It is capable of inspecting products that cannot stand on their own but can be suspended in place, such as screws, rivet nuts, and similar components.

- The system is designed to inspect screws with standard designs, covering lengths ranging from 5 mm to 80 mm.

- The eddy current probe can be added to inspect for issues like heat treatment presence, poor heat treatment, and dimensional errors, ensuring high-quality products are sorted and defects are flagged.

PRODUCT DETAILS

Customizable Solutions For Optical Sorting Machine

The machine is a highly adaptable device that can be tailored to meet specific client requirements. Its design allows it to handle objects that cannot stand upright, such as long screws, pulling caps, and similar items, making it versatile for various industrial applications.

Technical Capabilities

For standard-sized screws, the system can measure total lengths ranging from 10 to 80 mm, ensuring precise dimensional control. Additionally, the machine can be equipped with an automated optical inspection machine and an eddy current probe. This combination enables the detection of heat treatment issues and material mixing, allowing the system to automatically reject pieces with faulty dimensions or poor heat treatment.

Defect Detection and Precision

The optical sorting machine is designed to detect a wide range of defects, including broken needles, groove depth, multi-segment width and height, bottom shape, spacing between screw teeth, thread damage, and other critical parameters. The automated optical inspection machine ensures accurate and reliable detection, making it an ideal solution for inspecting and sorting screws. This combination of high-speed and high-precision makes the system a perfect choice for efficient screw sorting machine operations.

Industry Applications

The optical sorting machine is widely used in various industries, including automotive, aerospace, and general manufacturing, where precision and quality are paramount. Its ability to handle diverse objects and detect intricate defects makes it an essential tool for maintaining high standards in production processes.

By integrating the optical sorting machine into their quality control systems, manufacturers can achieve efficient, accurate, and reliable inspection, ensuring the delivery of high-quality products that meet industry specifications.

|

RELATED PRODUCT

Contact

HOW TO CONNECT